Business

How Turbo 400 Transmissions Are Built for Power? Learn

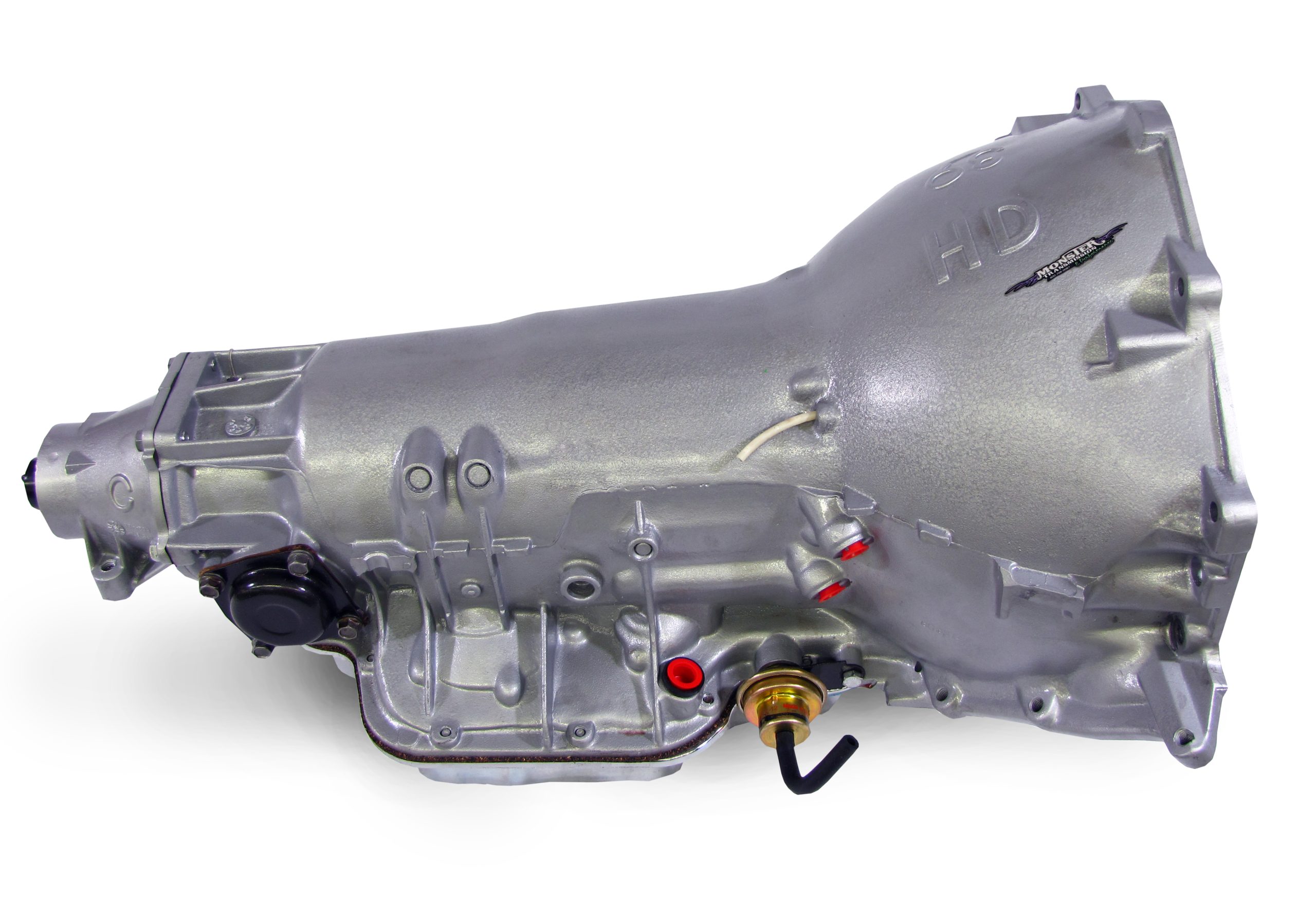

In the realm of high-performance transmissions, few can match the legendary Turbo 400 (TH400). Also known as the TH400, this three-speed automatic transmission has been a staple in muscle cars, hot rods, and high-performance vehicles for decades. What makes the TH400 stand out is not only its capability to handle immense power but also its durability and precision. In this article, we will take you behind the scenes to explore how TH400 transmissions are meticulously crafted and engineered to deliver unparalleled power and performance.

The Birth of a Legend

General Motors introduced the TH400 in 1964, and it quickly gained recognition for its ability to handle substantial horsepower and torque. This transmission was a response to the growing demand for high-performance vehicles, and it became a cornerstone in the muscle car era. Since then, the TH400 has evolved, but its core design principles have remained true to its original purpose: to transmit power reliably and efficiently.

Engineered for Power: Key Components

To understand how TH400 transmissions are built for power, let’s dissect the key components and design principles that make them so formidable.

1. Rugged Construction

At the heart of every TH400 transmission lies a rugged and robust design. These transmissions are engineered to withstand the stresses of high-horsepower engines, making them a popular choice in drag racing and other high-performance applications.

2. Heavy-Duty Torque Converter

The TH400 is equipped with a heavy-duty torque converter that efficiently transfers power from the engine to the transmission. This component plays a crucial role in launching the vehicle and ensuring smooth power delivery.

3. Strong Planetary Gearset

The planetary gearset within the TH400 is known for its strength and durability. This gearset is responsible for transmitting power and allowing the transmission to shift seamlessly between gears.

4. Smooth Shifting Performance

Despite its immense power-handling capabilities, the TH400 offers smooth and consistent shifts. This is especially important in drag racing, where precise gear changes can make the difference between victory and defeat.

5. Adaptability

While often associated with high-performance vehicles, the TH400 is versatile enough to be used in various automotive applications, from muscle cars to off-road vehicles and even trucks. Its adaptability showcases its prowess beyond the drag strip.

The Manufacturing Process

Now that we’ve explored the fundamental design principles of the TH400, let’s delve into the manufacturing process that brings these transmissions to life.

1. Precision Engineering

TH400 transmissions are the result of precision engineering. Skilled engineers meticulously design every component to meet exacting standards. Computer-aided design (CAD) and advanced simulation tools help optimize the transmission’s performance and efficiency.

2. High-Quality Materials

The use of high-quality materials is paramount in building a TH400 transmission that can handle power. Components are made from strong alloys and heat-treated steel to ensure longevity and reliability under extreme conditions.

3. Precision Machining

During the manufacturing process, each component undergoes precision machining. This ensures that parts fit together seamlessly and that critical tolerances are met. The precision of the machining process is essential for the transmission’s overall performance.

4. Rigorous Testing

Quality control is a top priority in TH400 transmission production. Every unit is subjected to rigorous testing to ensure it meets the highest standards for performance and durability. This testing includes checking for leaks, measuring clearances, and evaluating shift performance.

5. Expert Assembly

Skilled technicians assemble TH400 transmissions with meticulous attention to detail. Each unit is carefully inspected and calibrated to ensure that it functions flawlessly once installed in a vehicle.

Customization and Tuning

One of the remarkable aspects of TH400 transmissions is their ability to be customized and tuned to specific performance requirements. This customization allows for fine-tuning the transmission to match the engine’s power characteristics and the vehicle’s intended use.

1. Stall Speed Tuning

The torque converter’s stall speed can be adjusted to optimize launch performance. This customization is essential for drag racing, where achieving the right stall speed can lead to quicker and more consistent starts.

2. Shift Calibration

TH400 transmissions can be fine-tuned to optimize shift points. This ensures that the transmission delivers power precisely when needed, whether for acceleration or cruising.

3. Cooling and Performance Enhancements

Additional enhancements, such as upgraded cooling systems and reinforced internals, can be added to further enhance a TH400’s performance and durability in extreme conditions.

Conclusion

The Turbo 400 transmission is a testament to precision engineering and durability. Behind the scenes, skilled engineers and technicians work tirelessly to ensure that every TH400 transmission is built to handle power and deliver uncompromising performance. From its rugged construction to its precision machining and fine-tuning capabilities, the TH400 has earned its place as a legend in the world of high-performance transmissions.

Whether it’s propelling a vintage muscle car down the quarter-mile or providing reliable power to a modern high-performance vehicle, the TH400 remains a symbol of strength and engineering excellence. It is a transmission built for power, and it continues to be a favorite among automotive enthusiasts and racers who demand nothing but the best in performance and reliability. Lookout for Powerglide as well.